A Hempcrete House for Tarpon Springs, FL.

Summer 2012. We are building the first hempcrete house in Florida and one of a very few in America. Follow along as work progresses. We broke ground in mid-April and anticipate completion by November.

There are many hempcrete structures in Europe, but few in America. There are buildings in the south of France, but we found little information to compare with Florida's climate with hurricanes and high humidity. We really do not know how the house will perform so this will be a test house. We will be trying every feature of hempcrete houses we can. Once built, we will be monitoring performance to see how the structure holds up and what the operating costs are.

There are also maintenance issues. Hempcrete breathes well, and care must be taken to maintain it. Only lime-based paints can be used. They are more expensive and more difficult than the modern latex acrylic paints. Three coats are required for full coverage. The first owner might be careful, but how do you assure it will be properly maintained through a chain of owners? You won't get good hempcrete advice from Home Depot.

Hempcrete is famous for breathability. People say it is very comfortable and healthy. The natural materials reduce the effects of allergies and illness from chemicals. No formaldehyde, latex, urethanes or VOCs. Certainly something we are looking forward to enjoying, but these are subjective issues too difficult to measure.

Many hempcrete projects are large and expensive. Ours attempts to be hempcrete for the common man. Normally costs for Florida construction in the flood zone with its high wind loads runs about $200/SF. We anticipate $225/SF. There will probably be overruns since there are still many difficult unknowns such as our ceiling work. The high cost of building in flood zones tends to dilute the premium paid for hempcrete. If the operating costs are low enough however, it might be the most cost-effective construction technique for flood zones.

There are hidden costs too. Do you put a memory foam mattress outgassing formaldehyde in the bedroom? Synthetic fiber carpets with synthetic foam padding? Plastic laminate countertops? Laminated floors? You've spent large sums of money on a natural house. Are you going to throw it all away? But those synthetics can be 80 percent cheaper. Are you willing to increase your furnishings budget 4-5 fold?

Meanwhile, Tarpon Springs enjoys a charming old world style with its strong ethnic Greek roots. We want to show that we can build a 21st century house that fits the traditional qualities of the city. Strong and solid with enduring value. The lime washes used to paint hempcrete give it an Old World charm.

The Site

A 50x100 residential lot in the center of town is the site for our test house. It will be 1560SF, three bedrooms, two baths with a two-car garage. The site is near the Sponge Docks and Riverwalk tourist area, a block from the Pinellas Trail, a 40-mile bicycle trail that circumnavigates the county. A short walk downtown to shops and restaurants. You can live here without a car or use an electric vehicle with no range anxiety. Here's the "before" view. The large old camphor tree in the center of the lot must go. Sorry. We will plant a new tree.

Tarpon Springs' inner city area needs development and the city has recently completed a Community Redevelopment Plan. We hope this project will lead to other much deserved new developments in the neighborhood.

The site is urban so the good insulating properties of hempcrete will be important. One advantage of the urban zoning is you can use more of the lot. Urban zoning is greener than suburban sprawl. You are within walking distance of city services. The City encourages closer buildings with intimate attachment to the sidewalks and porches for more neighborly interaction.

Pinellas County experiences hurricanes and Tarpon Springs received a direct hit from a Category 3 hurricane on October 25, 1921 bringing 115 mph winds. Our site is in Flood Zone A about 8 blocks south of the Anclote River and its sponge docks so an extra foot or so of fill will be added to the building footprint to meet FEMA A-zone flood insurance requirements.

Design Goals

Besides testing the use of hempcrete and the new frontier of high insulation that it offers, there were other goals in mind as we designed the house. We wanted to maintain green credentials as best we could, though some compromises were required.

Our walls will be 12" thick for R30 insulation. The ceiling will also have 12" of hempcrete insulation, but it is a lighter mix. This adds load to the roof trusses and the garage door header. There are special fabrication details, some of which we just have to learn as we go. Hempcrete needs 45 days to cure and it needs to be shielded from the rain the first 10 days while it cures. Florida has a 6-month rainy season. Bureaucratic delays pushed us into the teeth of hurricane season - June through November. This means we had to put the roof on and fill the attic underneath - much slower and a more difficult process. Filling the walls at the very top and installing the insulation will be very hard.

It is difficult to go beyond R19 insulation with fibreglass batts. Where it is needed, a double wall technique is often used. So even though hempcrete appears expensive, for the insulation and renewability it provides, it is the more cost effective choice.

Some builders are starting to offer Icynene™ foam which is made of Polymethylene polyphenyl isocyanate or Methylene bisphenyl isocyanate depending on the grade. The MSDS for Icynene offers no advice for flammability (which could make it hard to get a building permit) nor does it offer advice for ingestion except to see your doctor. It also advises firefighters must wear respirators. They don't say why, but besides the usual suspects of carbon dioxide, carbon monoxide and nitrogen oxides, isocyanate combustion produces isocyanate vapor which is a lung irritant (asthmatics beware) and traces of hydrogen cyanide. Isocyanates are produced by reacting amines with phosgene which has been classified as a chemical weapon since WWI. Phosgene cannot be shipped. It must be produced where it is used. Bhopal was making isocyanates when that tragedy ocurred. So even though Icynene itself appears harmless, and probably is superior to urethane foams, its production is anything but. It is not renewable nor recyclable and will live forever in landfills. Taken together, it is not an economy you want to promote, and it's really a backward step from sustainability. As for its effects on people and infants, it is too new to say. People do become sensitized to isocyanates over time usually as eye/throat irritations or impaired lung function. In contrast, hempcrete offers a natural path away from the chemical industrial complex to healthy sustainable living.

Our site dictates hurricane standards mandatory for most of Pinellas County. 130 mph rated windows with similar wind loads for walls and roofs. The best roof to meet the high wind standards is a hip roof such as ours. People used to think that cement tile roofs are best in hurricanes, but modern research says modern fiberglas shingles work best. Our compromise is a dimensional shingle roof. Pavers in the driveway allow enough permeable surface for water to percolate down. Sometimes we get 2" of rain in 20 minutes which causes localized flooding. Hempcrete does not like to sit in water so it sits 12" above grade. This was easy to do since our slab had to be raised two feet anyway for flood purposes.

Hempcrete is said to reduce racking action in wood frame housing. Good for seismic areas and our hurricane wind loads. So even though hempcrete is said to take no loads, it still contributes structural strength, and a hempcrete house will be stronger than a conventional house. Hempcrete has virtually no tensile strength and pretty low compressive strength. Still, a 200 pound man could walk on it with reasonable care taken. Our attic fill is lighter and not compacted. Service access to the HVAC in the attic will require a thin sheet of plywood to distribute the load.

Flood zones typically have soft sandy soils. The floor slab is designed to float on the sand like a barge on a river. Over time, the soils settle unevenly and the slab cracks. Uneven settling can stress roof felts causing roof leaks. Cracks eventually run up the walls. Nobody knows what advantage if any hempcrete can offer, but it might be more resilient to cracking or it might be more easily repaired after cracks develop. Settling is very common in this region. Thirty years from now there will certainly be evidence.

Pinellas county does not experience sinkhole problems much, but our neighboring Pasco county to the north has had some bad experience with them. The drought years are the worst. Hillsborough to our east has farms that pump hard to save crops from freezing which produces large sinkholes. So extreme settling is not unusual in Florida and a little settling is very common.

We wanted to use high efficiency lighting such as LED lighting, but it really was not available in 2011. Early in 2012 we found many new options, but they were expensive. The LED lights themselves are expensive so manufacturers put them in their high end fixtures - a double whammy for costs. Halogen runs so hot you need a large can fixture in the ceiling so you get no aesthetic advantage over incandescent, and the best LED option was a 6" PAR fixture. So we will install 6" cans and replace our incandescents in the future when LED costs come down. We will install a few LED fixtures in the living/dining rooms.

Most Florida homes are all-electric since natural gas was never available. It has finally reached Tarpon Springs, and they have agreed to extend the gas main to reach us so we can use a gas-fired on-demand water heater, a gas stove and a gas dryer. Typically gas saves about 60% over electric in these pure heating applications. Our local utility has a nuclear plant (idle since 2009) and they are planning another. We are paying for the new nuclear plant even though we will not use it for another ten years or more. They still purchase a lot of power from fossil fuel sources so our natural gas should still result in a net reduction of CO2 until the second nuclear plant comes online.

Our hope is that we will have a low electric bill thanks to the high insulation and the natural gas. Provision is made for a future solar array since solar prices are dropping. We can't size the array until we have a year of electrical bills in hand.

Ceiling design proved to be a problem with hempcrete in the attic insulation. We chose MagnesiaCore board from Canada for the ceiling of the interior space and OSB for the garage ceiling. MagnesiaCore is very expensive. There is a much cheaper product with Chinese sourced material. Unfortunately, Florida had a very bad experience with Chinese sourced gypsum sheetrock to the point where prospective buyers won't buy a house with Chinese sourced materials. So we are avoiding Chinese sourced materials for now. We are using 6" insulation in the garage and 12" in the interior. Without the insulation, garage space in Florida is not usable space. It even damages cars.

FYI, gypsum (Calcium Sulphate Dihydrate) is made by pouring sulfuric acid over phosphate rock. The precipitate is sold for sheetrock while the remainder is converted to phosphate fertilizer. But if you do not wash out the sulfuric acid adequately, as happened with Chinese sheetrock, you get corrosive sheetrock that stings your eyes. It damaged electrical wiring, electronics, silver picture frames and people's health. Just an example of how seemingly innocuous materials can blow up on you. Every building material has some risks, but lime has been used for a couple thousand years, and no chemicals are used in its production so it should be very safe.

Flooring is a big decision for any house. Plastic laminates are the least expensive, but they don't fit the natural feel of a hempcrete house and they use urethane foam adhesives today to glue them down. Urethane adhesives often fail in Florida. Mold and mildew call urethane food. Doesn't do any good to have a mold-fighting wall with a mold-feeding floor so a wood floor should be a floating floor. Solid wood floors have high material costs and the installation costs are higher too. Engineered wood with a bamboo surface gave us the price we needed with faster installation. Bamboo is very renewable and comes in enough shades so we could match what we needed.

Carpets and drapes are another cost item, and we wanted natural materials again. We found an online source that made drapes from hemp fiber, but the color selection was extremely limited. Might still use it. Linen (flax fiber) has many choices and might be better. Restoration Hardware is selling handmade hemp fiber area rugs, but their biggest size is 10x14. We will need several. They take heavy abuse, and you can take them with you when you move so they might be a good value in the long run. Vacuum cleaners are not designed for the irregular surface of a hand-braided hemp rug so beating them is the best option when cleaning is required. Since nobody beats their carpets anymore, that can be a show-stopper for most people. On the flip side, there is probably no detergent too strong for hemp. You could probably use wood bleach (Oxalic acid) or a pressure washer.

Windows are a big choice to make. Pinellas County requires hurricane-proof glass all across the county now. This is an extra thick version of your car windshield. We wanted good insulation in the windows to keep up with the high R-value in the walls so we chose dual pane insulated glass. The hurricane glass mounts on the inside where a triple-pane would go so triple pane was not an option. Our windows are triple-pane but the void between the hurricane glass and the insulated dual pane is not evacuated. Should be good for noise. We chose Pella casement windows with dual pane and hurricane glass. The fire code dictates the size so you can escape a fire.

The windows have a 10-year maintenance free warranty. After that you pay for the repair service, and you do not find parts at Home Depot. Will second and third owners maintain the windows? Leaky windows will soak the hemp behind the exterior render. It can damage the wall if it does not have time to dry out. In most cases though, it will have time.

Our 2-Ton air conditioner will probably be over-sized. R-19 walls with hempcrete have been shown to be better than R-19 walls with traditional multilayer stud walls. There are no air gaps or thermal bridging to defeat the design. So we expect that R-30 with hempcrete will exceed what people might expect by extrapolating their R-19 experience. Air conditioning contractors are not familiar with R-30 designs so they won't trust their numbers. It just won't look right to them. There are few choices below 2 Ton cooling units from American makers. Asian sources make 1 Ton units but their air handlers are just single room units. The air volume is a function of the room size so the air handler does not shrink just because the condenser does. Air handlers however tend to be designed as a mated pair with the condenser so you might not get a small enough condenser to save any money.

The air conditioning industry will have to re-tool to address an R-30 world. That will require decades.

Despite hempcrete's famous breathability, water cannot get out if it is wetter outside. Florida has a damp climate, and an R-30 box is a well-sealed box so there is a risk that humidity still cannot get out of the house in time to be comfortable. Humidity rises with all activity like cooking, cleaning, bathing and exercising. A thermostat doesn't sense humidity and a humidistat could end up chilling the house colder than you want. So we are adding a dehumidifier because an air conditioner is the wrong tool to control humidity. These are surprisingly rare in Florida because we often run the A/C so much, but our goal is to not run the A/C much at all. Maybe the dehumidifier will not be needed, but it is virtually impossible to add later so then you just suffer without it.

This unit has a damper to pull outside air in or recycle internal air. With our gas appliances, we will have combustion products in the room so ventilation is important. The unit can run 24/7 independent of the A/C. It runs the air handler fan to circulate air throughout the house. Condensate is plumbed to the air handler sump. A small sump pump pumps it outside so there are no gravity flow lines to plug up outdoors as they commonly do in Florida.

Construction Issues

There are some points of concern during construction. The 2x6 studs are centered within the solid 12" walls. This makes it hard to change utilities during construction let alone years later. You must be very sure of your design with respect to where outlets and plumbing go. Or you might add extra empty conduit (we didn't) just because somebody might want to pull some new cable, perhaps fibreoptic, in the future.

As the framing finished up, it was clear that the great number of studs would cause issues for the hemp stuffing. Normally, 2x6 studs would be on 24" centers, but not in flood zone construction. They are much closer and they double up in many places to allow for windows and doors. The result is a narrower, almost random spacing.

There is no wind load performance data for hempcrete walls so we have to build the house as if it were sheathed conventionally. It will probably be shown that hempcrete walls perform better so stud spacing can be increased in the future. It will be many years before codes will recognize that. In reality, it is probably unlikely we will actually see sustained 130 mph winds.

Hempcrete has a long curing time: 45 days before you can apply the hard render. Actually, the full cure takes years so the walls continue to strengthen over time. The walls must be shielded from rain with plastic sheeting for ten days while it dries. After that you would only cover it if you faced tropical storm force wind driven rain. The render itself has curing issues. It is applied in two passes with a curing period between passes and a final cure before the topcoat can be applied. From our standpoint, the issue is that we will be working during the peak of rainy season and the hurricane season. We will experience some rough storms.

Hempcrete cannot support the weight of cabinets or shelving. Nailing strips must be added to the wall studs to support kitchen cabinets. Since we are applying a minimal finish on the interior, this nail strip would be exposed. We can cover that with a tile backsplash. Flatscreen TVs might be wall mounted. The studs are 3.5" from the surface so we will make a mounting for it, but the TV might never be moved.

Wet lime attacks the zinc on galvanized pieces. This opens up pathways for future corrosion. All galvanized parts must be painted where they come into contact with wet hempcrete. We used automotive spray primer. This is an issue for the roof trusses where galvanized strong ties and hangers are used extensively. Once fully cured after 45 days, this issue goes away. Cured hempcrete tolerates galvanizing just fine.

The decorative stone facade on the street side must keep a 1" air gap separation from the hemp wall to maintain breathability. Lime mortars must be used to maintain the porosity. Stainless steel ties must be used to transmit the wall forces into the studs. Lime mortars cure more slowly so the wall builder must be patient.

Fully cured hempcrete can hold nails and screws well enough to hang pictures, but any significantly heavy object must be tied back into the stud with long screws. This raises the unanswered question, "How do you find a stud buried behind 3" of hempcrete?" So far, stud finders don't work. Unless you plan to use ground penetrating radar to install your bookshelves, consider installing screws hidden behind the baseboards so common magnetic stud finders can locate them.

You can make an effort to make sharp corners and install metal bead to keep your render straight, but we are not that far from the saltwater and the metal will corrode over the years. Hempcrete is not strong enough to take abuse concentrated on the corners such as a hit from a riding mower. So we are rounding the corners. This required a special fabricated mold for the exterior corners. Oddly enough, it was easier to make round corners than it was to hold sharp corners and protect them from abuse. Hempcrete is very friable until it gets its rendered surface. Sharp corners are easily damaged before then. This is true for exposed corners on the interior too. You would do well to plan for rounded corners everywhere.

Our architect specified tongue-and-groove cedar roof decking over the eaves (conventional decking higher where it is not visible). This is an attractive and desirable feature, but it caused trouble designing an equally attractive soffit vent that could be easily replaced or maintained. In order to compute your ventilation required, divide your floorspace by 150 (300 if you have a roof vent). That is the square footage of "Net Free Area" you must provide. For example an 8 mesh screen has 62% net free area. Screen makers quote their NFA on their websites. Any mesh opening larger than 1/8" requires bug screens which reduces your NFA even more. So 8 mesh is the best choice.

What is Hempcrete?

Hempcrete is a biocomposite made of the inner woody core of the hemp plant mixed with a lime-based binder. The hemp core or "Shiv" has a high silica content which allows it to bind well with lime. This property is unique to hemp among all natural fibers. The result is a lightweight cementitious insulating material weighing about a seventh or an eighth of the weight of concrete. Fully cured hempcrete blocks float in a bucket of water. It is not used as a structural element, only as insulating infill between the frame members though it does tend to reduce racking. All loads are carried by internal framing. Wood stud framing is most common making it suitable for low-rise construction. Hempcrete buildings ten stories high have been built in Europe.

The material is mixed in mortar mixers for 1-2 minutes and stuffed by hand into the wall cavities. The wall is slip-formed with temporary wooden or plastic "shuttering" forming the inner/outer surface forms. The material is lightweight and can be moved easily about the site in tubs and passed up bucket-brigade fashion to workers filling the cavities. Site clean-up is easy. Simply till it into the soil.

The material is finished on the outside with a hard render coating about 20mm thick to protect it with a final colored topcoat finish added. The end result appears like any stucco finished building. The inside can be left natural or finished with lime plaster for a traditional look. We plan to leave a natural look to highlight the hempcrete.

Hempcrete was discovered in a bridge abuttment in France built in the 6th century. Since its rediscovery it has seen growing use in Europe. Industrial hemp is grown by certified commercial growers so the crop can be certified to be very low in THC. Hemp is not psychoactive. Given it has survived 14 centuries, people expect hempcrete buildings will have a long life.

Hemp itself is a beneficial crop requiring no fertilizer, weed killer, pesticide or fungicide. It grows so thickly that weeds cannot grow. Farmers grow it in rotation with other crops such as barley or rye. The crop following the hemp requires no weed killer because the hemp has driven weeds out. The hemp seed is harvested as a nutritious food supplement rich in Omega-3 oil, amino acids, protein and fiber. It is considered a "super food". The outer fibers are used for cloth usually as a blend with 45% cotton. The woody inner core is chopped to uniform size for our use. It has been traditionally used as animal bedding. Thoroughbred horse owners demand it.

For over 60 years, growing hemp in America has been illegal, because it resembles its psychoactive cousin Marijuana. It is grown legally in Europe, the UK and Canada through a system of licensed growers producing seed certified low in THC (<.05%). Farmers must buy their seed from these seed growers and their fields are inspected periodically. Our hemp must be imported from the UK. A new plant to process the hemp core is being built in Canada so there should be a North American supplier soon.

This added shipping reduces the carbon-negative feature of hempcrete in North America and adds to production costs. It causes additional logistic costs since we had to buy a 40-foot container of material and unload it immediately on site. You must have people waiting for the truck with rented equipment to empty it, and you need dry weather. The truck charges nearly a hundred dollars an hour wait time while you unload for half a day. We filled a two-car garage with our material leaving a 4 foot margin for work around the edges. You have to keep this material dry until used so plan for adequate tarps.

Why use Hempcrete?

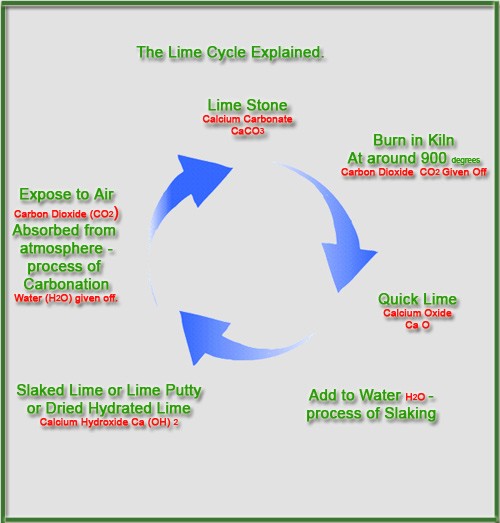

Hempcrete is carbon-negative. Cement production and use generates too much CO2 - the most of any man-made material. Lime production is a lower temperature process that produces much less CO2 which it reabsorbs during curing as it mineralizes back to calcium carbonate. The hemp plant absorbs carbon as it grows. The lime absorbs more CO2. The result is a material that consumes more carbon than it produces.

Florida is a coastal state severely affected by sea level rise from global warming along a thousand miles of coastline. Florida spends $4-$5 million per mile to renourish its beaches lost to erosion. Renourishing must be repeated every 10-15 years. Carbon negative construction therefore is extremely important to Florida. Streets in Tarpon Springs are often only 6 feet above sea level as they are in most of the barrier islands, the Keys and many coastal areas of the state. Some global warming extremists anticipate several feet of sea level rise by the year 2100 - essentially the life span of this house.

Hempcrete has good insulating properties and fills voids permanently. Traditional insulating batts leave gaps and often create more as the structure ages. Because of this, an R19 wall with hempcrete insulates better than an R19-rated wall of traditional multi-layer construction, and that should remain true as the building ages. It can also make very thick insulation that loose batts cannot easily do. Our house will be R30 with 12" thick walls. The lightweight nature allows it to be used as attic insulation too. Air conditioning costs are a big factor in Florida homeowners' budgets. Any technology that can produce reliable R30 insulation is very valuable to Floridians. R30 homes are just a whole new world. The home building industry has not seen it and neither has the air conditioning industry.

"R30" is a nominal rating. Your results will vary, and design features will affect the result. An R30 wall woould be 12" thick with a brick or Hardiboard facing and internal sheetrock. We chose not to do that. We will render the exterior for our hardfacing and we are not rocking the interior. Our wall will be about R28. Our flood codes required heavy closely spaced studs which reduces it more, but that applies to competing technologies too.

Lime Technologies UK publishes conductivity values for their proprietary Hemcrete™ product. The amount of binder used significantly affects insulation value. The values vary with the mix ratios (bag-to-bale ratio) used.

Note that these values are a significant improvement over earlier hempcrete data which was in the range of .08-.09 W/m-K. Some hempcrete applications use lime only which requires more lime. Proprietary binders such as Hemcrete™ add binding agents for strength such as pozzolans and portland cement. This reduces the amount of binder required which improves insulation. Consult your vendor.

Hempcrete also has good thermal mass. As the sun rises, the walls begin to heat up. As the sun sets, they release the heat back into the night sky. Thermal mass gives rise to thermal intertia: the walls cannot transmit heat into the living space until they themselves have heated up. A 12" wall is large enough that the occupants would see little oscillation in internal temperature. With no air conditioning or heating, the room fluctuates little from the mean temperature throughout the day. Unfortunately in Florida, the summer mean is about 85° F. So cooling is still required, but it will cycle on less. Often we only get one or two months a year when A/C is not needed so the thermal mass feature can extend that a few months a year making a significant A/C saving.

Besides thermal insulation, hempcrete offers good acoustic insulation as well. This will be important in busy inner city neighborhoods. We want to test that property. We are leaving the inner walls lightly treated. Often hempcrete walls are "rocked" over with porous magnesia sheetrock. In traditional multi-layer wall construction, the bulk of the noise is blocked by the sheetrock, not the insulating batts. We want to know if rocking the walls is required here for good noise reduction so that is another part of the test. The hard exterior render on hempcrete should help block noise.

High insulation brings on secondary problems: trapping moisture or making good homes for insects and rodents. Blown-in roof insulation is rat heaven and hollow wall construction is home for palmetto bugs (designer cockroaches - a Florida specialty), ant nests (fortunately, fire ants stay in the soil. Bull ants and carpenter ants don't.), lizard nests, wasp nests and sometimes bee hives. Hempcrete naturally avoids this so it has the potential to make very well insulated buildings with reduced pest problems. This hasn't been done before and leads to potentially large energy savings in the future. Air conditioning costs are a significant fraction of the building operating costs in Florida. We want the insulation, but we don't want the bugs and pests.

When the energy crises hit, we sealed our buildings up, but this brought a secondary problem: moisture accumulated and fed mold and mildew. Our internal environment became toxic as materials outgassed chemical vapors. Hempcrete seals well, but it is porous and breathes well. This breathability makes a comfortable house that controls humidity naturally. No condensation hence no mold and mildew, no clammy feeling. Cement block houses in Florida risk mildew growth from damp environments. It is a very serious problem - some houses are condemned for it. Unoccupied houses develop sick house syndrome so you are obliged to run the air conditioner when you are gone. Hempcrete's ability to breathe and inhibit mold and mildew will be very valuable. Hempcrete is a natural material with no toxic vapors.

The lime in hempcrete is also a good fire retardant. A 6" hempcrete panel wall section survived 73 minutes in a fire test. It did not support flames, but it charred and eventually lost structural integrity. A 12" block wall survived 110 minutes. Actually the hempcrete survived. The lime mortar holding the blocks failed. In case of fire, you have time to shower and pack a suitcase. We had no issues with the building department. We submitted fire test reports from England as an example of anticipated performance.

Many of our modern homes can achieve deadly flashover fires in minutes. There was no evidence in the fire test reports of hempcrete causing or supporting flashover. This is largely an issue of your furnishings. As we said earlier, are you going to stuff your natural hempcrete home full of unnatural fabrics, foams and poly fill cushions? So another benefit of a natural life is reduced flashover.

Termites are a serious issue in Florida. Formosan termites, notorious for heavy destruction in New Orleans, have arrived in Florida. By age 35, most houses have dry termites in the roof trusses. Fortunately, they are slow. It is the wet termites coming out of the soil you must fear. Hempcrete does not support termites and by embedding all our framing in hempcrete we reduce the potential for termite damage. The upper portions of our roof trusses are exposed, but wet termites coming up from the soil will have nothing to feed them.

Hempcrete is recyclable. When the house is demolished the material can be ground up and spread on farmers' fields. Concrete cannot do that. Landfill costs are a significant part of demolition costs. Eventually, landfills will become closed to construction debris. When that happens, construction must be recyclable. This is starting to happen in Europe. Old hempcrete can be used to make new hempcrete. You can recycle up to 10% of old material into your batch of new material. Cement cannot do that.

All of these features indicate hempcrete will be a valuable player in 21st century Florida, but we need to know how it performs in real-world Florida conditions: heat, humidity, tropical storms in an environment rich with mold, mildew and insects.

Hempcrete does not tolerate wet feet, but it tolerates rain well. It sits atop a 12" cement foundation to allow drainage. When it rains, moisture penetrates and dries out after the rain. A spray test in Scotland showed that after 72 hours, water had penetrated a few inches. Florida gets substantial rains, tropical storms and hurricanes. It should be a good test for hempcrete performance.

Notes on Production

First-time users may approach the wall casting process with trepidation, but after stuffing a row 15-20 feet long, you will have resolved most of your fears and concerns. The process is pretty fault-tolerant. There are many tips that can help. First, resist the temptation to tamp the material too hard. The R-value of wood is 1.4 per inch of thickness and that for hempcrete is 2.4. The more you tamp your material, the closer it approximates solid wood and not porous hempcrete. You can turn your R30 wall into R18. You also lose porosity for the breathability, and you consume more material. Just fill the voids and tamp sufficiently to achieve fiber-to-fiber contact so the material bonds to itself. In places like corners you can tamp harder to achieve strength. Secondly, lay your material evenly about 8" deep before tamping. Less, and you tamp too dense. Resist the temptation to begin tamping before this layer is fully done. Each of these layers leaves a striated appearance and you want them level, not wavy.

Wherever there are horizontal members such as windows, noggins or the top plate, stuffing will be difficult. There is high risk of leaving voids that aren't revealed until you pull forms. Sometimes you just have to patch those gaps by hand after the form is removed. Hempcrete patches well.

A batch of hempcrete remains workable for over an hour. Longer than that, and it should be recycled into new batches up to 10% of recycled material per batch.

You will use a mortar mixer, not a cement mixer. The blades of the mortar mixer toss the material and give it "loft" About the largest rental mixer you can find is an 8 or 9 cu ft machine. This can only do half a bale at a time which slows you down a lot. Any more, and the motor simply stalls. Wet hemp is heavy and binds between the walls of the tub and the blades. Most rental mixers are heavily encrusted with cement. It helps to bang as much as you can off to avoid loose pieces in your hemp mix. This is harmless, but it can mar your finish if you are looking for a natural finish as we are. Working this way, one man on the mixer can feed a four man crew along the walls.

For measuring purposes, we used 5-gallon buckets, and a 4-1-1 mix: 4 buckets of hemp, 1 bucket of binder and one bucket of water. Mix the water and binder for about a minute then add the hemp and mix another minute or so. One man on the mixer can feed 3-4 people along the wall stuffing hemp pretty well. The mixer was not the critical path to production. Moisture co0ntrol is important but not completely critical. The process tolerates many errors, but you will get sloppy results if you cannot achieve consistent batches. Too much water delays drying time. Too much binder reduces insulation.

Animal feed stores sell two-handled rubber baskets that are nice for hemp work in 6.5 gallon and 10.5 gallon sizes. Search online. These are good for pouring hemp into the forms. They are also larger than the 5-gallon buckets obtainable at building supply stores, and they take abuse well.

We used Geoplast™ panels from Italy imported through their rep in Canada as our shuttering system. A minor logistic problem there. Allow time for shipping and customs snafus. These panels are expensive, but reusable for many houses. They set up and re-position pretty quickly with their built-in clamps and keep the walls straight both horizontally and vertically. You can screw them directly against the studs with small screws when your studs are exposed as they are along our inner garage wall. When you need to set them off 3.5" as we do on our thicker walls, you can use quarter inch lag screws. When you withdraw the lag screws, you must push material in the holes. This can require some skill if you are not plastering over the surface defects.

The Geoplast panels were expensive so we never had enough, but they proved good for establishing a straight line for lining up additional plywood. Wherever there are penetrations, you must cut holes in the forms which cannot be repaired, but the process tolerates holes in the shuttering. You can tape over holes in the plastic forms with packaging tape.

Form setting is the critical pacing item. All work stops while you change forms for another row. All of your wall crew should be experienced form setters with sufficent screw guns and spare batteries. You do not want stuffing to wait while batteries are charging. You can pull shutters in a few hours. Hemp will stick a little bit so it helps to slide your form before you pull it. The plastic forms could be cleaned before setting them again.

Cured lime is harmless Calcium Carbonate, but Lime is caustic. The mixture is very hard on hands and exposed skin. Use heavy duty neoprene coated work gloves. Do not use disposable vinyl/latex gloves. The work is too hard and destroys them quickly. The mixer man should have a face mask. The loose powder is hard on lungs. Workers along the wall handling wet mix do not need face masks. That said, the next problem is getting workers to wear them. They don't want gloves and masks when it is 95° and 75% humidity.

Workers should have long sleeve shirts and long pants, but they won't do that in Florida. As a result minor scrapes get severely irritated with the lime on them. They turn brilliant red and take a week or two to heal. As a result worker turnover becomes a problem. You should have disinfecting wipes on hand and antibiotic creams. If they won't wear long clothing, consider barrier creams.

Maintaining consistent crews is often difficult. Laborers in the cement trades tend to be here today and gone tomorrow. This makes it hard to maintain consistent quality from day to day so errors like voids or poorly incorporated material start popping up. You can drop things in the wall and bury them in hemp resulting in surprises when you pull forms. Most of the time you can gouge out mistakes and patch material in the voids. However, they will be obvious patches if you are leaving the surface natural as we are on the interior.

We noticed abnormally large swarms of mosquitos even by Florida standards. At first, we thought it was an artifact of Tropical Storm Debbie, but mosquitos are attracted to CO2 and lime absorbs CO2. Your house is a CO2 sink drawing in CO2 and the CO2 is a mosquito magnet drawing in mosquitos. Even the bags of dry lime attracted them in our moist climate. Mosquito repellent was mandatory. You will know when your hempcrete has cured when the mosquitos stop knocking on your door at breakfast time.

Horizontal plastic conduit runs in the thinner garage walls proved to be a problem. It was hard to stuff well and left voids. The hemp did not bond to the plastic conduit and came away in chunks when we pulled forms. Hemp needs a couple inches to get good bonds with itself. Thin sections just crumble away. In most cases you want a minimum of 2" unless you are hiding it with something like cabinets. Within a 12" wall, this would not have been such a problem, but the risk of voids always exists with any horizontal members when you are stuffing vertically.

You need to design out problems like this before you start stuffing. You want to identify voids and ask yourself if they have to be there. Vertical voids can be stuffed. Horizontal voids are always difficult.

"Lightweight" is a relative term. Hempcrete is far lighter than cement but far heavier than traditional loose insulation used for attic fill. Hempcrete is very heavy until it dries. We were afraid that the attic fill would require temporary supports until dry. Drying is not curing. Drying just removes water. Curing is the process of absorbing carbon dioxide to mineralize the lime. Drying takes some few days depending on your climate. Curing takes 45 days. This wet weight issue affects your truss design. If you attempt to move too fast, you can overload your trusses. You might need truss supports as well as ceiling panel supports. All of this support material can be a very significant cost factor in your construction budget. We used 12mm Magnesiacore which is very strong material and no additional supports were required. We warned the truss manufacturer of the wet load weight and no unusual truss issues were evident.

You must protect the finished work from rain during curing and you must moisten the surface with a gentle spray mist as it cures so it dries evenly. We found a bulk tarp supplier online. We hung tarps from the rafters. We could roll them up to work and drop them quickly as the skies darkened with rain.

Cured hempcrete can be shaped with power tools and hand tools: recipricating saws, abrasive disks, sureform rasps, belt sanders et cetera. This allows you to touch up shapes and mistakes you want to fix. It is best to leave them until fully cured before working the surface. It does wear down blades and many tools must be treated as expendable.

Structural hempcrete is mixed to a 3:2 ratio of hemp bales to bags of binder. One bale of hemp with its binder yields 7 cubic feet of mix. Insulating attic fill is mixed to 1:1 ratio. We measured a yield of 8.75 cubic feet. This is dumped on the Magnesiacore and raked to the desired level. It helps to mark the rafters with chalk or a felt pen marker for the desired depth. You will also use dipsticks.

Once your walls are done, you want to begin plastering and rendering, but, you must wait long enough for the walls to dry. The hempcrete was not applied uniformly moist and it does not dry uniformally. Therefore general rules cannot be written. Measure it. Use a moisture meter with accessory probes that can reach the middle of your walls. Our exterior surfaces dropped to 20% moisture within a week pretty consistently all around. The interior of the 12" walls were 45% moisture after a month, but not consistently. There were several wet spots running 75%. The walls will continue drying for years, but you want them dry enough to take plaster and not affect any color work you want either as colored plasters or lime washes.

ALT wants the moisture below 15% at a depth of 30mm before plastering begins. Use a pin type meter with accessory depth probes. It is easy to spear a flake of hemp shiv on the meter pins and carry that reading over to other points along the wall so take care to clean your meter probes with every reading. Moisture migrates down to the foot of the wall so the bottom measurements will be the critical path to your plastering work. There will be wide variation in the first few weeks until the walls stabilize. We were trying to dry our walls as Hurricane Isaac passed by on its way to the panhandle.

Our interior finish is a natural look finish. A thin coat of plaster is applied and washed with a wet sponge float to reveal the texture. We learned that we had to point up the worst divots or they would give a swiss cheese appearance. The pointing team works with a slack mix and proceeded the plasterer by an hour or less. About an hour after plastering, the surface could be scrubbed with the rubber float. Do not wait overnight.

Generally, lime plasters are slower and more forgiving than gypsum plasters and lime renders are more forgiving than portland stucco mixes. You can even recycle clean wastage into your next batch. You would have to keep a clean dropcloth under you and the labor probably isn't worth it. You rod the exterior render to get a straight surface. The scraped material could easily be vacuumed up and reused.

Sources

Lime Technology (UK) Producer of Tradical HF hemp fiber and Tradical HB binder. Distributor of Baumit renders.

American Lime Technology American distributor of Tradical Hemcrete fiber and binder. Purveyor of USHG lime mortars and washes. Source of our lime paints and interior stucco mix.

Geoproducts Corp. North American distributor of plastic Geopanel shuttering (Geoplast, Italy).

Contacts